About Us

As a global business, we are aware of our responsibility to lead by example and safeguard the planet for future generations.

BKT is committed to sustainability through the continuous assessment of our environmental impact and the implementation of more sustainable practices. Our sustainability strategy addresses a number of different causes, including working to reduce our carbon footprint and discovering more sustainable materials, to supporting the local communities that we work in.

Explore the environmental, social, and business drivers behind our corporate sustainability goals and view our latest sustainability report.

BKT keeps faith in fundamental values such as sharing, generosity, and strength that permeate our business activities worldwide, helping us look towards the future without fear.

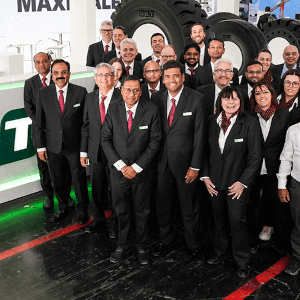

At BKT, people are the heart of everything we do. Our motto of ‘Growing Together’ reflects our commitment to supporting our global community, and taking care of our people, their well-being and the environment that they live in.

For our 10,000 colleagues across our group companies in India, Europe and North America, we offer a unique corporate culture with a focus on innovation and growth.

Meet our team and hear about life at BKT from our leaders across the globe.

A passion for innovation and a commitment to continuous improvement is at the core of our business. We are driven by our desire to meet the changing needs of our customers and ensure that they have access to the tires of the future.

Our independent Research and Development Centre in Bhuj, India is at the core of our innovative product design and development, allowing us to continuously develop our products using more sustainable materials.

Learn more about our latest product launches and innovations.

[1].jpg)