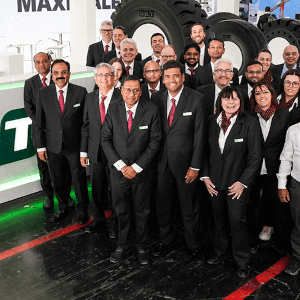

A special guest today on the blog: Mr. Dilip Vaidya, BKT President and Director Technology, who places research and innovation at your service day by day.

Dear readers, today we aren’t going to tell you the story of one of our users, but that of a special guest, who is part of the BKT management. It’s Mr. Dilip Vaidya, BKT President and Director Technology, who places research and innovation at your service day by day. He will tell us something about his amazing job and how a new BKT tire is born.

BKT always looks ahead!

The BKT Research and Development Center deals with everything concerning tire technologies and innovation: from designing a product novelty, to creating new compounds to improve tire performance, and to implementing more efficient manufacturing processes.

Mr. Vaidya thoroughly explains the reason why the constant commitment of the R&D Division culminates right in the design stage: “Customer satisfaction is our first and foremost objective. It’s our drive for constantly looking for new solutions that make BKT products even more reliable, more competitive and highly technological”.

Within the BKT R&D Center, there are different facilities, such as the Analytical and the Chemical Laboratories, the Physical Laboratory, the outdoor testing track and a special engineering unit for All Steel radial tire prototypes. All these teams work in close cooperation with one another in every phase of the process.

The making of a tire

When a new tire is designed, some steps need to be followed. But let’s listen to the words of the expert: “The first thing to do is to observe the requirements the product has to satisfy in terms of performance and positioning. You need to set the dimensions of the tire, and then develop and create the mold and all accessory products. Next, you produce the first tire sample on which you perform specific analyses to fine-tune the product and every feature. You test its resistance under several aspects, and last but not least the tire can be included in the production line and launched on the market.”

So many steps need to be kept under control to offer outstanding performance and satisfy users. Yet, BKT’s job doesn’t end here! The R&D Division continues monitoring the product for further improvements. Mr. Vaidya adds: “After a new BKT product has entered the market, the R&D Division strictly surveilles its performance in the several applications on international markets. The aim of constantly monitoring our product range is to have always updated data available to assess every possible improvement area of the product.”

Have you noticed the workload behind each product? A very stimulating interview, and many thanks to Mr. Vaidya. We hope he’ll tell us soon more interesting aspects of his job…so, stay tuned!